Table of Contents

Car Buffing

Introduction

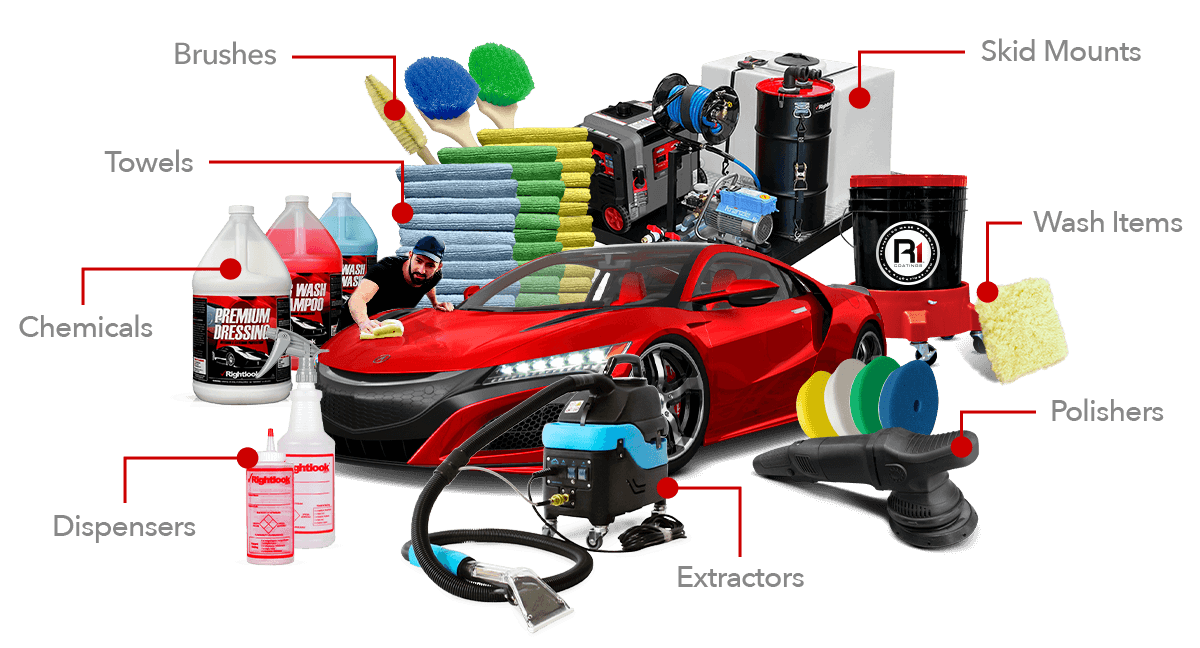

Achieving a professional-grade polish on your car might seem daunting, but with the right tools, techniques, and a bit of patience, you can make your vehicle look like it just rolled out of the showroom.

Buffing not only enhances the appearance of your car but also helps protect the paint from environmental damage. This guide will walk you through the basics of car buffing, from understanding the different types of buffers to mastering the techniques needed for a flawless finish.

Understanding Car Buffing

Definition and Purpose of Buffing

Car buffing is the process of using a machine or manual tool to apply a buffing compound to the car’s surface to restore its shine and remove imperfections. The primary purpose of buffing is to eliminate minor scratches, oxidation, and other blemishes from the car’s paint, resulting in a smoother, glossier finish. Buffing can significantly enhance the appearance of a vehicle, making it look newer and more well-maintained.

Benefits of Buffing Your Car

- Improves Appearance: Buffing removes minor surface imperfections and oxidation, giving your car a clean and polished look.

- Protects Paint: By smoothing out the paint surface, buffing helps to prevent future damage from environmental contaminants and UV rays.

- Enhances Resale Value: A well-maintained, shiny exterior can increase your car’s resale value by making it more appealing to potential buyers.

- Prolongs Paint Life: Regular buffing can extend the life of your car’s paint by removing harmful elements that can cause deterioration over time.

- Restores Gloss: Over time, a car’s paint can become dull due to exposure to the elements. Buffing restores the original gloss and shine, making the car look vibrant and new.

Differences Between Buffing and Polishing

While buffing and polishing are often used interchangeably, they are distinct processes with different purposes:

Buffing:

- Purpose: Primarily used to remove surface imperfections such as scratches, oxidation, and swirl marks.

- Method: Involves the use of a buffing machine and a more abrasive compound to cut through the top layer of paint or clear coat.

- Outcome: Results in a smoother surface and restores a significant amount of shine and clarity to the paint.

Polishing:

- Purpose: Focuses on refining the surface after buffing to achieve a high-gloss finish. Polishing can also be done without prior buffing if the paint is in good condition.

- Method: Uses a less abrasive polish or compound and a polishing pad to enhance the shine and smoothness of the paint.

- Outcome: Produces a mirror-like finish and enhances the depth and clarity of the paint, but doesn’t remove deep imperfections like buffing does.

Types of Buffers

1. Orbital Buffers

Orbital Buffers, also known as Random Orbital Buffers, operate with a random, elliptical motion. This means the pad moves in both a circular and an elliptical motion, which helps to minimize the risk of creating swirl marks or holograms on the paint.

- How They Work: The pad moves in a random orbit, which ensures that no single spot on the paint is worked on continuously. This random movement helps distribute the polishing or buffing action more evenly across the surface.

- Advantages:

- Less Risk of Damage: The random motion reduces the risk of creating swirl marks or burning the paint.

- Ease of Use: Generally more user-friendly, making them suitable for beginners.

- Versatility: Can be used for both polishing and light to moderate correction.

- Disadvantages:

- Less Aggressive: May not be as effective for heavy paint correction or removing deep scratches.

2. Rotary Buffers

Rotary Buffers have a single, continuous rotation motion. The pad spins in a circular direction around a fixed axis.

- How They Work: The pad rotates around a single point, which means the entire surface is worked on in a consistent manner. This direct approach is effective for cutting through imperfections.

- Advantages:

- Effective for Heavy Correction: Excellent for removing deep scratches and oxidation due to their powerful, direct action.

- Professional Use: Preferred by professionals for its effectiveness in aggressive correction.

- Disadvantages:

- Risk of Damage: Higher risk of creating swirl marks, burns, or holograms if not used correctly.

- Requires Skill: More challenging to use, especially for beginners, as it requires precise control to avoid damage.

3. Dual Action (DA) Buffers

Dual Action (DA) Buffers combine the features of both orbital and rotary buffers. They have a dual-motion action where the pad rotates and oscillates simultaneously.

- How They Work: The pad both spins and moves in an oscillating pattern. This dual action provides the benefits of both rotary and orbital movements.

- Advantages:

- Balanced Performance: Offers a good balance between cutting power and safety, making it suitable for a variety of tasks.

- Reduced Risk of Damage: The oscillating motion reduces the likelihood of creating swirl marks and provides a more controlled application.

- Versatile: Effective for both light to moderate correction and polishing.

- Disadvantages:

- Less Aggressive than Rotary: May not be as effective for heavy paint correction compared to rotary buffers.

Preparing Your Car for Buffing

1. Washing and Drying the Car

Washing and drying the car are fundamental steps to remove loose dirt and debris that could cause scratches during the buffing process.

- Washing:

- Use a Car Shampoo: Choose a pH-balanced car shampoo specifically designed for automotive paint. Avoid household cleaners or dish soaps as they can strip wax and harm the paint.

- Two-Bucket Method: Use one bucket for the soapy water and another for rinsing the wash mitt. This helps prevent transferring dirt back onto the car.

- Drying:

- Use a Drying Towel: After washing, use a clean, dry microfiber towel or a dedicated drying towel to gently pat the car dry. Avoid dragging the towel across the surface, which could cause scratches.

- Blotting Technique: For best results, use a blotting motion rather than wiping, which can help prevent streaks and reduce the risk of scratching.

2. Claying the Surface to Remove Contaminants

Claying is a process that removes embedded contaminants that are not removed by washing alone. This step ensures a smooth surface, which is essential for effective buffing.

- Clay Bar:

- Choose the Right Clay: Use a clay bar or clay mitt designed for automotive paint. There are different grades of clay, with fine clay being suitable for most cars.

- Lubricate the Surface: Spray a clay lubricant or detailing spray onto the surface. This helps the clay bar glide smoothly over the paint and reduces the risk of scratching.

3. Taping Off Sensitive Areas

Taping off sensitive areas protects trim, plastic, and rubber components from accidental damage during the buffing process.

- Choose the Right Tape:

- Painter’s Tape: Use high-quality painter’s tape or automotive masking tape that adheres well and removes cleanly without leaving residue.

- Masking Tape: For delicate areas, use automotive masking tape designed to handle curves and irregular shapes.

- Apply the Tape:

- Trim and Molding: Tape off areas like door handles, trim pieces, and moldings where the buffer or compounds might cause damage or leave residue.

- Rubber Seals: Protect rubber seals and weatherstripping around doors and windows to avoid damage or accumulation of compounds.

Buffing Techniques

1. Applying the Compound or Polish

Applying the right product effectively is crucial for successful buffing.

- Choose the Right Product:

- Compound: Used for removing deeper defects and scratches. It’s typically applied with cutting pads.

- Polish: Used for refining the finish and enhancing gloss. It’s generally applied with polishing or finishing pads.

- Application Method:

- Apply Product to the Pad: Apply a small amount of compound or polish directly to the buffing pad. For compounds, use a bit more product as they often need more lubrication.

- Dab the Product: Dab the product on the car’s surface in several spots. This helps distribute the product evenly and prevents overloading the pad.

2. Working in Small Sections

Working in small sections ensures even application and better control.

- Section Size:

- Smaller Areas: Work on small sections, typically about 2×2 feet (60×60 cm) at a time. This prevents the product from drying out or curing before you’ve had a chance to work it in.

- Process:

- Start with a Clean Pad: Begin with a clean pad for each section. If the pad becomes saturated or contaminated, switch to a fresh one.

- Overlap Sections: Slightly overlap each section to ensure complete coverage and avoid missing spots.

3. Using the Correct Speed and Pressure

Adjusting speed and pressure properly ensures effective buffing without damaging the paint.

- Speed:

- Low to Medium Speed: For most applications, use a lower to medium speed setting on your buffer. High speeds can generate excessive heat and risk burning the paint.

- Speed for Compounds: Start at a lower speed when applying compounds to spread the product evenly, then increase speed slightly to work the compound in.

- Pressure:

- Moderate Pressure: Apply moderate, consistent pressure. Too much pressure can cause damage, while too little can result in ineffective correction.

- Let the Buffer Do the Work: The weight of the buffer should provide most of the pressure. Avoid pressing down too hard, as it can cause heat buildup and uneven results.

Addressing Common Buffing Issues

1. Swirl Marks

Swirl marks are fine, circular scratches often caused by improper washing techniques or buffing with a dirty pad.

- Causes:

- Dirty or Contaminated Pads: Using a pad with trapped dirt can cause fine scratches.

- Improper Washing: Washing with a dirty cloth or sponge can introduce swirl marks.

- Incorrect Buffing Techniques: Using excessive pressure or incorrect pad movements can also create swirl marks.

2. Holograms

Holograms are reflective patterns that appear as swirls or lines, often caused by improper buffing techniques or using the wrong products.

- Causes:

- Rotary Buffers: High-speed rotary buffers can create holograms if not used correctly.

- Over-Buffing: Excessive buffing in one area can lead to holographic patterns.

- Improper Product Use: Using products not suited for the pad or paint can also result in holograms.

3. Burn Marks

Burn marks are caused by excessive heat generated during the buffing process, which can damage the paint.

- Causes:

- High-Speed Buffing: Using too high a speed on a rotary buffer can create excessive heat.

- Excessive Pressure: Applying too much pressure can cause overheating of the paint.

- Prolonged Buffing: Buffing the same area for too long can also result in burn marks.

Finishing Touches

1. Final Polishing Steps

Final polishing helps to refine the paint, remove any residual haze left from the buffing process, and enhance the overall gloss.

- Choose a Finishing Polish:

- Type: Use a finishing polish or glaze, which is less abrasive than compounds and is designed to add depth and shine to the paint.

2. Applying a Sealant or Wax for Protection

Sealant and wax provide protection and enhance the shine of the paint. They create a barrier against environmental contaminants and UV rays.

- Choose the Product:

- Sealant: Synthetic sealants offer long-lasting protection and a high-gloss finish. They typically last longer than waxes.

- Wax: Natural or hybrid waxes provide a warm, deep shine and can be easier to apply. They typically need more frequent reapplication.

- Application:

- Apply to a Cool Surface: Ensure the surface is cool and dry before applying sealant or wax. Avoid applying in direct sunlight.

- Use Appropriate Tools: Apply the product with a clean, soft applicator pad or sponge. For sealants, use a thin, even layer. For waxes, apply a thin layer and allow it to haze before removing.

3. Inspecting Your Work for Missed Spots or Imperfections

Inspecting the finished product is essential to ensure that no areas were missed and that the paint correction is consistent throughout.

- Visual Inspection:

- Lighting: Use good lighting, ideally natural light, to inspect the surface. Walk around the vehicle and look at the paint from different angles to catch any imperfections.

- Touch Test: Run your hand over the surface to feel for any areas that might still be rough or uneven.

- Addressing Missed Spots:

- Rebuff If Necessary: If you find missed spots or imperfections, you may need to perform a targeted rebuff with a light polish or compound, depending on the severity.

- Additional Coating: Apply additional sealant or wax if certain areas were missed or if the finish needs further enhancement.

Conclusion

Detailing your car effectively involves careful preparation, correct techniques, and safety precautions. Start with thorough washing and claying, then use the right buffing and polishing methods to achieve a glossy finish.

Regular maintenance, including washing and waxing, helps protect and enhance your car’s appearance. Always prioritize safety by handling chemicals and tools properly and ensuring good ventilation.